Functional fillers

UPM BioMotion™ are wood-based renewable functional fillers (RFF) from UPM Biochemicals for innovative and sustainable solutions in the chemical industry.

Given the urgent need to reduce CO2 emissions from rubber products, they offer a sustainable alternative to replace the two dominant fossil-based fillers in rubber products - carbon black and precipitated silica.

The Portfolio is based on biochemicals produced from certified sustainable and regional hardwood and sawmill waste in a biorefinery in Leuna.

The UPM BioMotion™ products can make a significant contribution to improving the sustainability of end-use applications in the rubber industry, in particular through weight reduction and significantly lower CO2 emissions. The functional fillers are mainly used in elastomers, which are used in various applications including the automotive industry, floor coverings and shoe soles.

The production process is patent-protected and unique worldwide.

In addition to the improved carbon footprint, UPM BioMotion™ products also have greater purity. Furthermore, they enable a weight saving of up to 25 percent in rubber applications compared to fillers based on fossil raw materials. For the automotive industry in particular, weight savings mean higher mileage, lower costs and an additional reduction in CO2 emissions.

Only recently, the European Rubber Journal ranked these products as number one in the top 10 projects for new, sustainable elastomers. Furthermore, UPM Biochemicals' investment in the biorefinery in Leuna has made it to the finalists in the competition for the German Corporate Sustainability Award 2022 and has been shortlisted for Chemical Week's Sustainability Awards.

Based on its specific surface area ranging from 10 m²/g – 40 m²/g, they fall into the category of semi-reinforcing functional fillers. Due to the polar nature of its surface, RFFs show a strong interaction and reinforcement in polar rubbers, like NBR, AEM, ACM, and FKM. In non-polar rubbers, like EPDM, SBR, or NR, typically lower levels of reinforcement are achieved in direct comparison to traditional functional fillers with similar specific surface areas

Currently, there are three grades to offer with a different specific surface area between 10m2/g and 40m2/g. There is ongoing development to expand the product range shortly

They are available in pellet (granulate) format. They should be stored in a clean, dry space away from exposure to high temperatures, open flames. Pelletized Grades are much easier to handle due to significantly better flow and conveying properties. They would be commercially available in big bags (2m3) and low melting PE bags (EVA) ranging from 5kg to 20kg.

| UPM BioMotionTM | X10 | X20 | X40 |

|---|---|---|---|

| STSA Surface Area [m2/g] | 11 | 23 | 40 |

| pH | 6 - 10 | 6 - 10 | 6 - 10 |

| Sulfur Content [%[ | < 0.2 | < 0.2 | < 0.2 |

| Benzo[a]pyrene [ppm] | < 0.1 | < 0.1 | < 0.1 |

| Each of 22 FDA PAHs [ppm] | < 1 | < 1 | < 1 |

| Loss on Drying [%] | < 3 | < 3 | < 3 |

MISTRON© Talc Series - a functional mineral for rubber

MISTRON© Talc Series products are functional minerals, not simple fillers.

MISTRON© VAPOR products provide the rubber formulator with flexibility to balance the benefits of improved processability with higher product performance. MISTRON© VAPOR products occupy a unique position in the rubber industry and have been used succesfully for more than 50 years.

MISTRON© VAPOR Talc Series - improve your mechanical properties!

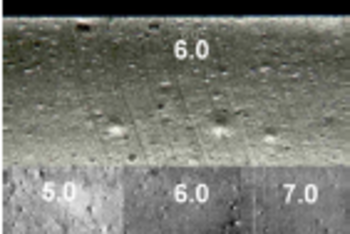

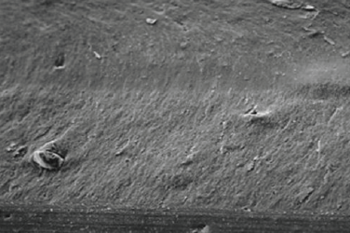

MISTRON© VAPOR is an ultra-fine, micro-lamellar, highly pure, hydreated magnesium silicate specifically developed for the rubber industry. Its platy morphology, organophilic nature, high aspect ratio and surface area result in superior reinforcement and rheology plus permeability resistance for thermoset rubbers.

MISTRON© VAPOR is an extremly soft mineral with a Mohs hardness of one. This property reduces wear on processing equipment compared with other minerals. MISTRON© VAPOR has less than 0.2% absorbed water, which eliminates pre-drying and allows it to be used in liquid-medium cure systems without encountering porosity problems. MISTRON© VAPOR is an electrical insulator and chemically resistant mineral eliminating electrochemical degradation in window seals and hoses plus providing solutions in wire and cable.

MISTRON© VAPOR functions as ...

... Processing Aid providing ...

- Reduced Mixing Times

- Lower Compound Viscosities

- Reduced Heat Generation

- Superior Compound Flow

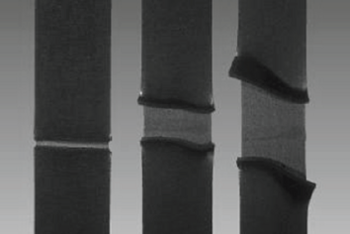

- Improved Extrusion Rate and Quality

- Better Dispersion of Reinforcing Fillers

- Reduced Elasticity / Nerve

- Higher Green Strength

.. Reinforcement improving ...

- Tensile Properties

- Tear Properties

- Fatigue Performance

- Flaw Resistance

- Improved Thermal Performance

- Superior Weathering

... Improvement for wire and cable

- Chemical and Electrochemical Resistance

- Electrical Insulating Properties

MISTRON© HYPERPLATE™ Speciality talc

New Innovative MISTRON© HYPERPLATE™ ULTRA for Superior Barrier Performance

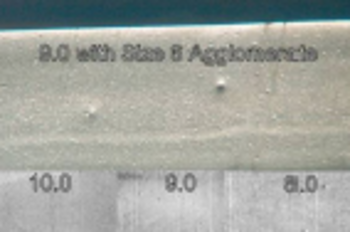

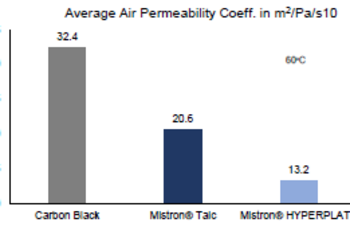

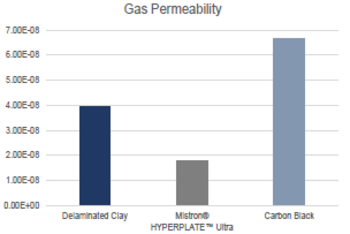

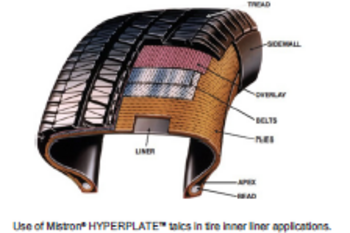

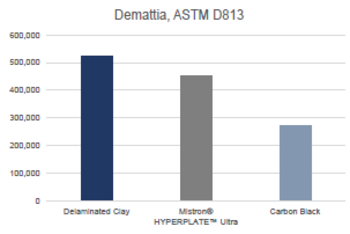

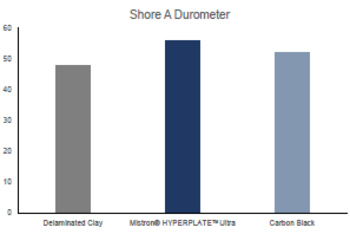

MAGRIS TALC has recently developed a higher aspect ratio HYPERPLATE™ talc for superior barrier performance. In extensive studies multiple talc grades has been tested and MISTRON© HYPERPLATE™ ULTRA was found to be the best performer in Gas Permeability (ASTM D1434) and DeMattia Flex Crack (ASTM D813) against the most commonly used Carbon Black Control and Clay. MISTRON© HYPERPLATE™ ULTRA's gas permeability is 3 times lowerand also sustained about twice the amount of DeMattia Flex Cycles when compared to the Carbon Black Control.

| Product | Form | Application | Benefits | D50 sedigraph | D98 sedigraph | Brightness [GEB] |

|---|---|---|---|---|---|---|

| SILVERLINE© 002 | Natural white powder, bags | Dusting, relase agent talc | Excellent partioning low cost agents | 8,4 | 55 | 75 |

| VERTAL© 92 | Natural white powder, bags | Dusting | Powdering, cable layer insulation | 17,5 | 45 | Y72 |

| VERTAL© 97 | Natural white powder, bags | Dusting | Powdering, cable layer insulation | 2,2 | 31 | 86 |

| MISTRON© VAPOR R (powder) | Natural white powder, bags | Non-black compounds, EPDM roofing, MRG, hoses, weather stripping | Processability, reinforcement, durability and toughness | 2,2 | 31 | 86 |

| MISTRON© VAPOR R (compacted) | White powder compacted, bags | Non-black compounds, EPDM roofing, MRG, hoses, weather stripping | Processability, reinforcement, durability and toughness | 2,2 | 31 | 86 |

| MISTRON© VAPOR RE | Natural white powder, bags | Black compounds, window seals, MRG | Processability, reinforcement, durability and toughness | 2,2 | 31 | 80 |

| MISTRON© VAPOR ULTRA | Natural white powder very fine, bags | Black compounds, window seals, MRG | Processability, reinforcement, durability and toughness. Improve extrudate surface quality, enhanced elongation at break | 2 | 12 | 88 |

| MISTRON© CB* | Surface treated powder, bags | Medical stopper, MRG, hoses, seals and gaskets, printed circuit boards | High modulus and good compression set | 2,2 | 31 | 86 |

| MISTRON© CB6* | Surface treated and finer and densified, bags | Medical stopper, MRG, hoses, seals and gaskets, printed circuit boards | High modulus and good compression set | 2 | 25 | 88 |

| MISTRON© HYPERPLATETM | Delaminated talc, extreme lamellar, bags | Tire inner liners automotive, fuel and hydraulic hoses | Superior permeability resistance, flex fatigue, long life, fire retardancy | 1,2 | 8 | 80 |

| MISTRON© HYPERPLATETM ULTRA | Delaminated talc, extreme lamellar, bags | Tire inner liners automotive, fuel and hydraulic hoses | Superior permeability resistance, flex fatigue, long life, fire retardancy | 1,5 | 10 | 83 |

| MISTROFOAM©* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, foamed polymer products | High modulus and good compression set, Improved water resistance and electrical properties in wire and cable | 2,2 | 31 | 82 |

| MISTRON© ZSC* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, gaskets | High modulus and good compression set, Improved water resistance, higher dielectrical stregths, properties in wire and cable | 2 | 25 | 87 |

| MISTRON© TZ2* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, gaskets | High modulus and good compression set, Improved water resistance and electrical properties in wire and cable | 2 | 25 | 87 |

| MISTROPHOBE* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, gaskets | High modulus and good compression set, reaktive chemistry with any unsaturated cure system, that enhances hydrophobicity, wet electrical performance and mechanical properties | 2 | 25 | 88 |

* = surface treated

| Product | Appearance | Specific surface area BET [m2/g] | Ash content [%] | Sieve residue > 45μm [%] | pH value |

|---|---|---|---|---|---|

| LUVOMAXX® Silica HM 1160 | White powder | 145 - 175 | ≤ 6 | ≤ 0.5 | 5 – 8 |

| LUVOMAXX® Silica HM 2160 | White granules | 145 - 175 | ≤ 6 | ≤ 0.5 | 5 – 8 |

| LUVOMAXX® Silica HM 1170 | White powder | 160 - 190 | ≤ 6 | ≤ 0.5 | 5 – 8 |

| LUVOMAXX® Silica HM 2170 | White granules | 160 - 190 | ≤ 6 | ≤ 0.5 | 5 – 8 |

| LUVOMAXX® Silica HM 1180 | White powder | 165 - 195 | ≤ 6 | ≤ 0.5 | 5 – 8 |

| LUVOMAXX® Silica HM 2180 | White granules | 165 - 195 | ≤ 6 | ≤ 0.5 | 5 – 8 |

| Product | Appearance | Specific surface area BET [m2/g] | Sieve residue > 45μm [%] | pH value |

|---|---|---|---|---|

| LUVOMAXX® Silica HM 200 | White powder | 170 - 230 | ≤ 0.05 | 3.6 – 4.5 |

| LUVOMAXX® Silica HM 300 | White powder | 270 - 330 | ≤ 0.05 | 3.6 – 4.5 |

| LUVOMAXX® Silica HM 380 | White powder | 350 - 410 | ≤ 0.05 | 3.6 – 4.5 |

Our parnter and supplier BRISIL has developed a patented process for the resource-efficient production of "green" silicas from biomass (rice husks - rice-husk ash), which are used as functional fillers in tyres, shoe soles, conveyor belts and cables. The following types are available:

| Product | Appearance | Specific surface area BET [m2/g] | Ignition loss [%] | pH value |

|---|---|---|---|---|

| BSIL 1100 | white powder | 80 - 120 | ≤ 6 | 5.5 – 7.5 |

| BSIL 1100 MP | white microgranules | 80 - 120 | ≤ 6 | 5.5 – 7.5 |

| BSIL 1130 | white powder | 120 - 140 | ≤ 6 | 5.5 – 7.5 |

| BSIL 1130 MP | white microgranules | 120 - 140 | ≤ 6 | 5.5 – 7.5 |

| BSIL 1180 | white powder | 170 - 190 | ≤ 6 | 5.5 – 7.5 |

| BSIL 1180 MP | white microgranules | 170 - 190 | ≤ 6 | 5.5 – 7.5 |

| BSIL 1200 | white powder | 190 - 210 | ≤ 6 | 5.5 – 7.5 |

| BSIL 1200 MP | white microgranules | 190 - 210 | ≤ 6 | 5.5 – 7.5 |

| BSIL 2160 MP (highly dispersable) | white microgranules | 150 - 170 | ≤ 5 | 5.5 – 7.5 |

| BSIL 2180 MP (highly dispersable) | white microgranules | 170 - 190 | ≤ 5 | 5.5 – 7.5 |

| BSIL 2200 MP (highly dispersable) | white microgranules | 190 - 210 | ≤ 5 | 5.5 – 7.5 |

| Product | Appearance | Active ingredient | Brightness | OAN (ml/100g) | Density (g/cm³) | Specific surface area BET (m²/g) |

|---|---|---|---|---|---|---|

| Mica Concord 200/325 | Off-white powder | Wet-ground mica, muscovite | n.a. | 75 | 2.85 | n.a. |