LUVOCOM® 3F - Materials for Extrusion Based Processes

Our LUVOCOM 3F materials take account of the process and final product during the design stage and are therefore able to achieve another level of properties and quality. All our products are thoroughly tested in our development laboratory, which ensures that they work in all the systems available on the market.

Below you will find information on our commercially available products, including data sheets and pictures.

We have many more materials under development so if you still have not found the solutions that you are looking for, simply contact us!

Download LUVOCOM 3F brochure.

is a high-performance polymer from the PAEK family. It has outstanding mechaniccal properties combined with excellent thermal and chemical resistance. Our material does not require a heated building chamber to be printed and it exhibits enhanced layer bonding, thus reducing the anisotrpy of the final part.

Comparison of Performance

LUVOCOM 3F PEEK 9581 NT is a pure PEEK that has been optimized for the FFF 3D printing process. The high-performance material offers superior mechanical properties in all directions (XY, ZX) compared to standard PEEK filaments, as well as competing PAEK family filaments. LUVOCOM 3F PEEK 9581 NT is engineered so that it can be printed without the use of a heated print chamber, though implementing the annealing process will lead to better crystallinity and material performance. This results in printed parts that rival injection molded components in terms of performance.

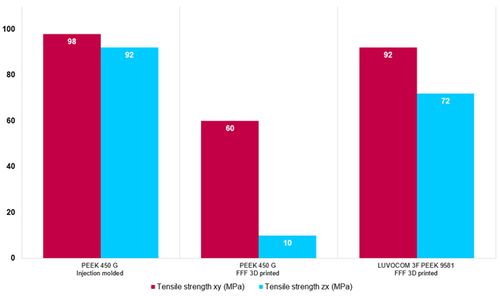

PEEK, e.g. Victrex® PEEK 450 G, has a typical tensile strength of 98 MPa for injection molded specimen. The weld line strength is about 92 MPa. Both values are measured on ISO test bars. The standard test is on test bars filled from one side (red framed image below). The test bar for the weld line strength is filled from two sides simultaneously, which creates a weld line in the middle of the bar (blue framed picture below).

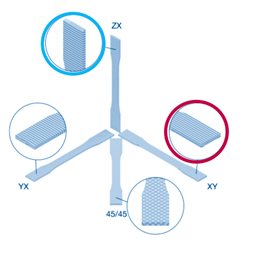

Typical values for FFF printed specimen, based on standard PEEK, are in the area of 60 MPa in xy direction and 10 MPa for zx direction. Below image demonstrates the position and print orientation in the FFF process.

LUVOCOM 3F PEEK 9581 NT achieves 92 MPa in xy and 72 MPa in zx. These values are close to the level of injection molded specimen and are higher than values achieved with other PAEK products that are also especially optimized for FFF. Below diagram shows all data in comparison.

| Product | Description | Technical Data Sheet |

|---|---|---|

| LUVOCOM 3F PEEK 9581 NT | Modified neat grade | Click here |

| LUVOCOM 3F PEEK CF 9676 BK | Carbon fiber (CF) filled grade. | Click here |

| LUVOCOM 3F PEEK GF 9761 BK | Glass fiber (GF) filled grade | On request |

is a high-performance polymer from the PAEK family. It has outstanding mechaniccal properties combined with excellent thermal and chemical resistance. PEKK in comparison to PEEK can be processed at lower temperatures and provides a higher glass transition temperature (Tg). Our material will print semi crystalline and does not require a heated building chamber to be printed and it exhibits enhanced layer bonding, thus reducing the anisotropy of the final part. For challenging applications it should be post-treated by annealing to enhance its mechanical and thermal properties.

| Product | Description | Technical Data Sheet |

|---|---|---|

| LUVOCOM 3F PEKK 50082 NT | Modified neat grade | On request |

is a high-temperature polyamide-based material. It has the strength of a PA6 without sacrificing any of its printability. The water uptake is half and its absorption rate is four times slower when compared with standard PA6. No heated chamber ist required and no warping is observed. It is compatible with HIPS and PVOH support materials.

| Product | Description | Technical Data Sheet |

|---|---|---|

| LUVOCOM 3F PAHT® 9825 NT | Modified neat grade | Click here |

| LUVOCOM 3F PAHT 9936 BK | Modified unfilled type for optimized component surfaces | Click here |

| LUVOCOM 3F PAHT® 9826 BK | Tribologically optimized neat grade | Click here |

| LUVCOM 3F PAHT® 9875 NT | Modified neat grade with an even lower water uptake | Click here |

| LUVOCOM 3F PAHT® CF 9742 BK | Carbon fiber (CF) filled grade | Click here |

| LUVOCOM 3F PAHT® 9743 BK | Highly filled with carbon fiber (CF), not suitable for filament production | Click here |

| LUVOCOM 3F PAHT® CF 9891 BK | Modified carbon fiber (CF) filled grade with even lower water uptake | Click here |

| LUVOCOM 3F PAHT® KK 50056 BK FR | Ceramic spheres filled, flame retardant (UL 94 V0 at 0.4 mm with printed specimen, fulfills requirements of EN 45545) | On request |

| LUVOCOM 3F PAHT® GK 9874 NT | Glass sphere filled grade | On request |

is our entry-level product based on a polyethylene terephthalate material. It is the easiest fiber-filled material to print on the market. There are no issues with retraction and no need for a heating chamber. It exhibits a superb surface finish straight from the printer, thus reducing the need for post-processing. It can be post-treated to enhance its mechanical properties. It is compatible with HIPS as a break-away or soluble support.

| Product | Description | Technical Data Sheet |

|---|---|---|

| LUVOCOM 3F PET CF 9780 BK | Carbon fiber (CF) filled grade | Click here |

is a random copolymer polypropylene material. It has good mechanical properties combined with outstanding chemical resistance and low density. Our material does not require a heated building chamber to be printed and it exhibits enhanced layer bonding, thus reducing the anisotropy of the final part.

A PP build plate is recommended for the neat material.

| Product | Description | Technical Data Sheet |

|---|---|---|

| LUVOCOM 3F PP 9929 NT | Modified neat grade | Click here |

| LUVOCOM 3F PP CF 9928 BK | Carbon fiber (CF) filled grade. | Click here |

is a poly(p-phenylene sulfide) material. In addition to having inherent flame retardancy, it has outstanding chemical resistance properties combined with excellent thermal and dimensional stability. Our material does not require a heated building chamber to be printed.

| Product | Description | Technical Data Sheet |

|---|---|---|

| LUVOCOM 3F PPS CF 9938 BK | Carbon fiber (CF) filled grade. | Click here |

3D Printing Lab-Video

Please accept the External Content Cookie option if you want to play this video. Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.