Functional Fillers

Mineral Fillers

MAGRIS TALC series - lamellar and microcrystalline talcs for Paints & Coatings applications

Mineral fillers for paint and coatings improve or influence technical and / or optical properties such as colour, hiding power and brightness. They are used to increase the volume, change the material density value and reduce the formulation costs of end customers. Other properties can be the anticorrosion protection in lacquers, influence of rheology in paints, increase scratch resistance and improve UV protection or flame-resistance of end products.

| Rheology Performance | Physical Properties |

|---|---|

|

|

ARTIC MIST®, CIMPACT®, JetWhite®, JetFill®, JetFill®M, MAGRIS TALC MISTRON®, NICRON®, SIERRALITE®, SILVERLINE®, STELLAR®, VERTAL®, YELLOWSTONE®

In the modern world of paint industry today, talc is more than a simple mineral filler. MAGRIS TALC offers highly lamellar talc products as well as microcrystalline and engineered types fine-grades reduced.

Bright white JETWHITE® und MISTRON® products as well as cost-effective NICRON® and SILVERLINE® products offer the laboratory developer a high degree of flexibility to balance the advantages of technical colour performance and improved process ability with rising raw material prices and higher production output.

| Product | Form | Application | Benefits | D50 sedigraph | D98 sedigraph | Brightness [GEB] |

|---|---|---|---|---|---|---|

| JetWhite® 1H/HC | Natural white powder, submicron talc, bags | Additive for decorative paints, can coating | For maximum hiding power and brightness, TiO2 extender | 1.1 | ca. 6 (Hegman 7.5) | Y90 |

| JetWhite® 7H/HC | Natural white powder, ultrafine talc, bags | Additive for decorative paints, can coating | For maximum hiding power and brightness, TiO2 extender | 1.9 | ca. 8 (Hegman 7) | Y91 |

| NICRON® 665 | Natural white powder, microcrystalline talc, bags | Architectural and industrial primers and topcoats | Film strength and flexibility, provides barrier properties, very bright | 1.2 | ca. 9 (Hegman 6.5) | 87 |

| MISTRON® MONOMIX | Natural white powder, micronzed talc, bags | Engineered and high performance, industrial and primers, protective coatings | High surface area and tight top-size control, anticorrosive functionality, rheology contribution | 2 | ca. 10 (Hegman 6) | 88 |

| NICRON® 604 SILVERLINE® 604 | Natural white powder, microcrystalline talc, bags | Architectural and industrial primers and topcoats | Film strength and flexibility, provides barrier properties, improve corrosion resistance and stain-blocking ability | 2.3 | ca. 12 (Hegman 6) | 85 |

| STELLAR® 510 | Natural white powder, lamellar talc, bags | Architectural and topcoats where high brightness is needed | Film strength and flexibility, provides barrier properties, very bright | 5 | ca. 15 (Hegman 5.5) | Y88 |

| SILVERLINE® 504 | Natural white powder, microcrystalline talc, bags | Architectural and industrial primers, non-color sensitive applications | Improve corrosion resistance and stain-blocking ability, improve sag resistance and maximize prime pigment extension | 3.2 | ca. 20 (Hegman 5) | 81 |

| NICRON® 403 MISTRON® 403 | Natural white powder, microcrystalline talc, bags | Architectural, wood and industrial primers and topcoats | Film strength and flexibility, provides barrier properties, semi-transparent wood stains to prevent tannin bleed, improve corrosion resistance and stain-blocking ability | 4.7 4.5 | ca. 25 (Hegman 4) | 83 86 |

| JetWhite® 4H | Natural white powder, medium talc, bags | Decorative paints, architectural and industrial primers | Improve barrier properties which impart corrosion resistance and stain blocking ability | 5.7 | (Hegman 4-4.5) | Y90 |

| VERTAL® 77 | Natural white powder, talc/carbonate mineral pigment, bags | Waterborne primers architectural and industrial, stain-blocking primers, sealers, undercoaters | Provides a unique balance of prime pigment spacing (opacity), film reinforcement, anti-cracking and barrier properties | 9 | ca. 25 | 78 |

| NICRON® 303 | Natural white powder, microcrystalline talc, bags | Architectural, wood and industrial primers, also adhesive, sealant, caulk, joint compound, wood putty, and auto body patch applications | Film strength and flexibility, provides barrier properties, improve corrosion resistance and stain-blocking ability, good sandability | 7 | ca. 30 (Hegman 3) | 82 |

| MISTRON® 303 NICRON® 302 | Natural white powder, microcrystalline engineered talc, bags | Protective coatings and marine coating applications, architectural flat exterior latex paints | Disperses easily in high-solids and solvent-borne coatings, good paint stability, rheology and anti-settling properties. Low sheen, good touch-up, good fade- and chalk-resistance | 7.5 13 | ca. 35 (Hegman 3) | 80 84 |

| VERTAL® 92 | Natural white powder, talc/carbonate mineral pigment, bags | Auto Rep Grouts, Car Putties Autofill | Highly lamellar talc, macrocrystalline 200 Mesh, good sanding for abrasive paper use | 17.5 | ca. 45-50 | Y72 |

| SILVERLINE® 202 | Natural white powder, microcrystalline engineered talc, bags | Airless-spray architectural waterborne flat paints | Engineered talc recommended where low viscosity build pigments are required, providing excellent sheen control, scrub resistance with minimal wear on airless spray equipment | 19.8 | ca. 50 (Hegman 2.5) | 76 |

| JetWhite® 2H | Natural white powder, coarser talc, bags | Decorative paints, architectural and industrial primers | Improve barrier properties which impart corrosion resistance and stain blocking ability | 11 | ca. 60 (Hegman 2) | Y87 |

| JetFil® M200 | Natural white powder, bags | General purpose applications for coarse talcs | High purity, platy, coarse talc | 10 | ca. 60 (Hegman 2) | Y78 |

| SILVERLINE® 001 | Natural white powder, bags | Industrial floor screed, coarse filler | Concrete form lubricant, parting agent for rolled asphalt, roofing, floor tile | 14 | ca. 40 - 60 | off white |

| VERTAL® AF | Natural white powder, UL Environment labeled for sustainability, only BB 2000 lbs | Construction, Bitumen Roofing, Flooring, Adhesives, Sound Damping | Talc with high magnesite content | 23 | 325 Mesh (44 µm) %passing 60-85 | off white |

MAGRIS TALC series - natural talcs for putties and liquid compounds, adhesives and sealings

MAGRIS Talc products are high-purity, functional additives ideal for putties and liquid compounds. Talc improves dimensional stabilityand reinforces putties and liquid compounds, giving added protection, against cracking and shrinking. Talc is the industry standard for sanding properties and polishing properties.

For putties and liquid compounds, adhesives and sealants we can offer also products from VERTAL® series with carbonic binding.

| Applications | Physical Properties |

|---|---|

|

|

| Product | Form | Application | Benefits | D50 sedigraph | D98 sedigraph | Brightness [GEB] |

|---|---|---|---|---|---|---|

| NICRON® 302 | Natural white powder, bags | Sealants and Caulks, Pressure Sensitive and Structural Adhesives | High loading low viscosity, high brightness | 13 | ca. 30 (Hegman 3) | Y82 |

| SILVERLINE® 303 | Natural white powder, bags | Pastes & Mastics, cementitious and self-leveling Compounds, fine | Finer top-size for smooth Finishes and application properties | 6,1 | ca. 40 | 78 |

| VERTAL® 92 | Natural white powder, talc/carbonate mineral pigment, bags | Auto Rep Grouts, Car Putties Autofill | Highly lamellar talc, macrocrystalline 200 Mesh, good sanding for abrasive paper use | 17,5 | ca. 45 | Y72 |

| VERTAL® 97 | Natural white powder, talc/carbonate mineral pigment, bags | Pastes & Mastics, cementitious and self-leveling Compounds | Highly lamellar talc, macrocrystalline 200 Mesh, good sanding for abrasive paper use | 15 | 50 | Y72 |

| SILVERLINE® 002 | Natural white powder, bags | Pastes & Mastics, cementitious and self-leveling Compounds | High loading low viscosity | 8,4 | 55 | 75 |

| VERTAL® TC-100 | Natural white powder, talc/carbonate mineral pigment, bags | Pastes & Mastics, cementitious and self-leveling Compounds | Improves resistance to cracking, smoothing and sandability, macrocrystalline 200 Mesh | 16,4 | 325 Mesh (44 µm) %passing 88 | off white |

| VERTAL® AF | Natural white powder, UL Environment labeled for sustainability, only BB 2000 lbs | Construction, Bitumen Roofing, Flooring, Adhesives, Sound Damping | Talc with high carbonate (Mg) content, improved dimensional stability, cross-flow mechanical performance, and flexural stiffness | 23 | 325 Mesh (44 µm) %passing 60-85 | off white |

Talc is oleophilic which gives it the ability to associate with liquid resins such as alkyds, epoxies, polyesters, acrylics, amines and polyols. In doing so, they create weak bonds with these resins that result in increased low-shear viscosity. When shear is applied the bonds break quickly, resulting in shear-thinning rheology that is ideal for many applications.

Mineral fillers improve or influence technical and / or optical properties such as colour, hiding power and brightness. They are used to increase the volume, change the material density value and reduce the formulation costs of end customers. Other properties can be the anticorrosion protection in lacquers, influence of rheology in paints, increase scratch resistance and improve UV protection or flame-resistance of end products.

Wollastonite

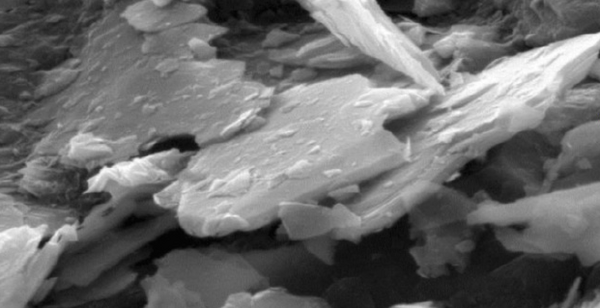

In its pure form, WOLLASTONITE is a rod-shaped material with a siliceous character. Known as a calcium metasilicate, the mineral is acquired by open-cast mining. The rod shape is preserved during the subsequent refinement by treating the product with as much care as possible. This forms a unique material with an aspect ratio of up to 10:1. This structure enables its use as reinforcing filler on a microscopic level.

The FILLEX forms are silanised versions of the WOLLASTONITE for better incorporation into organic systems. Universal use is possible due to various dressings.

| Product | Rod Length max. | Markets and Applications Good experience | Technical performance | Aspect-Ratio [L/D] | Brightness [comp. 100% MgO] |

|---|---|---|---|---|---|

| KEMOLIT KWB-1010 | 10 μm | Lacquers in general, powder lacquers, adhesives | Corrosion inhibitor through alkaline potential, adhesion, reinforcement | 3 : 1 | 84 |

| FILLEX-9AE1(KW)* | 10 μm | Lacquers in general, powder lacquers, adhesives | *Surface treated, corrosion protection, weather resistant | 3 : 1 | 82 |

| KEMOLIT KWB-1020 | 20 μm | Lacquers in general, powder lacquers, adhesives | Corrosion protection, structural donor, adhesion, reinforcement | 3 : 1 | 82 |

| KEMOLIT KW-1025 | 30 μm | Lacquers in general, powder lacquers, adhesives | Corrosion protection, structural donor, adhesion, reinforcement | 7 : 1 | 80 |

| FILLEX 7AE1 (KW)* | 30 μm | Lacquers in general, powder lacquers, adhesives | *Surface treated, corrosion protection, weather resistant | 7 : 1 | 80±2 |

| KEMOLIT KW-4 | 55 μm | Construction chemical applications in general | Reinforcement, against shrinkage and warpage, stable in joint compounds | 4 : 1 | 78 |

| KEMOLIT KW-3 | 70 μm | Construction chemical applications, adhesives and sealants | Reinforcement, stable in joint compounds, high brightness | 4 : 1 | 78 |

| KEMOLIT H-3 | 70 μm | Construction chemical applications, adhesives and sealants | Against shrinkage and warpage, volume-stable, economical | 4 : 1 | 66 |

| KEMOLIT KWB-200 | 80 μm | Construction chemical applications in general, adhesives and sealants | Reinforcement, corrosion protection, high brightness | 3 : 1 | 81 |

| KEMOLIT KW-1 | 125 μm | Construction chemical applications in general, adhesives and sealants | Against shrinkage and warpage, volume stable, good brightness | 5 : 1 | 76 |

| KEMOLIT H-60 | 200 μm | Construction chemical applications, mortars, concrete and stucco compounds | Reinforcement, stable in joint compounds, economical | 6 : 1 | Off white |

| KEMOLIT KSV-60N | 250 μm | Construction chemical applications in general, adhesives and sealants | Reinforcement, corrosion protection, high brightness | 9 : 1 | 72 |

| KEMOLIT KW-60 | 250 μm | Paints in general, powder coatings, adhesives | Corrosion and weather resistant, structural donor | 6 : 1 | 70±2 |

| FILLEX 2AH3(KW)* | 250 μm | Construction chemicals, adhesives, paints | *Surface treated, dimensional stability, better bonding | 8 : 1 | 70±2 |

| KEMOLIT KW-HW | 250 μm | Adhesives and sealants | Volume-stable, weather-resistant | 10 : 1 | 68 |

| FILLEX 1AF1(KW)* | 250 μm | Colours in general | *Surface treated, corrosion and weather resistant | 10 : 1 | - |

| KEMOLIT KM-60 | 500 μm | Industry, powder coatings, construction in general | Dimensional stability, structure provider, reinforcement | 7 : 1 | - |

| KEMOLIT D-1 | 1.000 μm | Construction in general, cementitious materials, mortar | Reinforcement, against shrinkage and warpage, stable in joint compounds | 5 : 1 | - |

Lightweight Fillers

Cenospheres OMEGA-SPHERES®

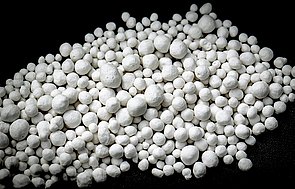

Hollow ceramic microspheres are extremely resistant hollow spheres, which are formed under the exposure of extreme heat. Temperatures over the relevant melting points are required to achieve a ceramic melting. Drops with a hollow are formed as a result of the subsequent rapid cooling process. The OMEGA-SPHERES® formed in this way are refined and fractionated in subsequent processes, thus being a high-quality raw material in your formulations.

The spheres we provide are produced at various production sites for global availability. Globally produced standard types are manufactured in Turkey, Central Asia and Germany. Special types are produced in Germany. There are further suppliers in Europe and throughout the world.

OMEGA-SPHERES®, White

Description

OMEGA-SPHERES® W are marked by a particularly high thermal resistance, low iron content and a white colour. They are available in different distribution particle sizes.

Application

Because of their particularly high heat resistance, OMEGA-SPHERES® W are preferentially used in the refractory and foundry industries. The white colour allows their use in aesthetically demanding applications such as decorative plasters and wall paints.

| Products | Particle size [μm] | Bulk density [kg/m³] | Crush strength [MPa] | Temperature max. [°C] |

|---|---|---|---|---|

| OMEGA-SPHERES® W150 | 0 - 150 | 410 | 25 | 1,600 |

| OMEGA-SPHERES® W300 | 0 - 300 | 410 | 25 | 1,600 |

| OMEGA-SPHERES® WM | 150 - 300 | 390 | 25 | 1,600 |

| OMEGA-SPHERES® W250-6 | 250 - 700 | 400 | 25 | 1,600 |

The stated values correspond to typical values and hence do not represent a specification.

Cenospheres THERMO-SPHERES®

THERMO-SPHERES®, White

Description

THERMO-SPHERES® W are white, high quality hollow ceramic microspheres < 150 μm, which are characterised by a high degree of fineness as well as a particularly high mechanical strength. The products are pre-dried and usable for foundry industry. The white colour allows their use in aesthetically demanding applications such as decorative plasters and wall paints.

Application

THERMO-SPHERES® W are used in bright applications which require the use of the smallest possible microspheres or make high demands on surface quality. This includes applications in addition to the use in paints and coatings, surfaces as well as special casting compounds and adhesives where a high whiteness is advantageous.

| Products | Particle size [μm] | Bulk density [kg/m³] | Crush strength [MPa] | Temperature max. [°C] |

|---|---|---|---|---|

| THERMO-SPHERES® W100 | 0 - 100 | 400 | 25 | 1,600 |

| THERMO-SPHERES® W125 | 0 - 125 | 400 | 25 | 1,600 |

The stated values correspond to typical values and hence do not represent a specification.

MATSUMOTO MICROSPHERES® MBF, expanded

Description

Thermally expanded hollow microspheres as 50 % masterbatches.

Application

Blowing agent for extrusion and injection molding; as granules, very good handling and metering properties.

| Products | Pellet size [μm] | Pellet density [g/cm³] | Temperature min. [°C] | Temperature max. [°C] |

|---|---|---|---|---|

| MBF-190EVA50 | 3-5 x 2-5 | ~ 0.9 | 130 – 140 | 185 – 195 |

| MBFN-190SSPE | 3-5 x 2-5 | ~ 0.9 | 160 – 170 | 210 – 220 |

| MBFN-170EVA | 3-5 x 2-5 | ~ 0.9 | 185 – 195 | 170 – 190 |

| MBF-230PE | 3-5 x 2-5 | ~ 0.9 | 180 – 190 | 220 – 230 |

| MBF-260EVA | 3-5 x 2-5 | ~ 0.9 | 190 – 200 | 250 – 260 |

MATSUMOTO MICROSPHERES®, moistened expanded grades

Description

MATSUMOTO MICROSPHERES® of the F-E series are moistened, polymer-based hollow microspheres that make handling much easier and safer. The solids content is about 10 %. The specific weight is in the range of 0.02 to 0.04 g/cm³, which allows a significant reduction of the final product weight.

Application

Lightweight fillers for a wide range of applications where a reduction in density, improvement in insulation as well as mechanical properties and rheological properties are desired. The expanded hollow microspheres show good temperature and solvent resistance and exhibit broad compatibility with a wide variety of a wide range of systems. Pre-expanded microsphere grades do not require elevated process temperatures.

| Products | Average Particle Size [μm] | Polymer | Effective Density [g/cm³] | Solids content [%] | Solvent resistance |

|---|---|---|---|---|---|

| F-30E | 30 – 60 | VC/AN-Copolymer | 0.020 – 0.030 | 9 – 13 | • |

| F-50E | 40 – 60 | Acrylnitril-Copolymer | 0.020 – 0.040 | 11 – 16 | •• |

| F-65E | 40 – 60 | Acrylnitril-Copolymer | 0.020 – 0.030 | 9 – 13 | •• |

Solvent resistance: low: • medium: •• well suited: •••

MATSUMOTO MICROSPHERES®, dry expanded grades

Description

MATSUMOTO MICROSPHERES® hollow microspheres of the F-DE series are pre-expanded, dry polymerbased hollow microspheres. The solids content is at least 97 %. The specific gravity is in the range of 0.010 to 0.035 g/cm³, as a result of which very light end products can be realized.

Application

MATSUMOTO MICROSPHERES® of F-DE are used in applications where a subsequent expansion of the hollow microspheres is not possible or undesirable.

| Products | Average Particle Size [μm] | Polymer | Effective Density [g/cm³] | Solids content [%] | Solvent resistance |

|---|---|---|---|---|---|

| FN-80SDE | 20 – 40 | Acrylnitril-Copolymer | 0.020 – 0.030 | ≥ 97 | •• |

| F-65DE | 40 – 60 | Acrylnitril-Copolymer | 0.025 – 0.035 | ≥ 97 | •• |

| F-80DE | 90 – 130 | Acrylnitril-Copolymer | 0.015 – 0.025 | ≥ 97 | ••• |

| FN-78DE | 100 – 200 | Acrylnitril-Copolymer | 0.010 – 0.020 | ≥ 97 | ••• |

Solvent resistance: low: • medium: •• well suited: •••

MATSUMOTO MICROSPHERES®, expanded hybrid

Description

MATSUMOTO MICROSPHERES® of the MFL series are hybrid hollow microspheres, which are used as a novel functional filler developed. They are polymer-based spheres that are coated with an inorganic powder.

Application

MATSUMOTO MICROSPHERES® MFL have a high elasticity and resistance, so that they can be used even when incorporated under high pressure. The surface coated with inorganic powder enables strength-increasing anchoring of the hollow spheres in the matrix used in each case.

| Products | Average Partice size [μm] | Coating | Effective Density [g/cm³] | Temperature resistance [°C] | Characteristic |

|---|---|---|---|---|---|

| MFL-81GTA | 10 – 30 | Talc | 0.20 - 0.26 | 130 – 140 | Very fine surface |

| MFL-81CGA | 10 – 30 | Calcium carbonate | 0.20 - 0.26 | 130 – 140 | Very fine surface |

| MFL-SEVEN | 20 – 40 | Calcium carbonate | 0.11 - 0.17 | 130 – 140 | Very fine surface |

| MFL-HD30CA | 20 – 40 | Calcium carbonate | 0.11 - 0.17 | 140 – 150 | High pressure |

| MFL-HD60CA | 50 – 70 | Calcium carbonate | 0.10 - 0.14 | 140 – 150 | High pressure |

| MFL-100MCA | 60 – 70 | Calcium carbonate | 0.10 - 0.14 | 150 – 160 | High pressure |

| MFL-110CAL | 90 – 120 | Calcium carbonate | 0.06 - 0.10 | 160 – 170 | Ultra light |

| MFL-UPR60 | 50 - 75 | Calcium carbonate | 0.10 - 0.14 | 140 – 150 | High pressure |

The values given are typical values and therefore do not represent a specification.

MATSUMOTO MICROSPHERES® expandable

Description

MATSUMOTO MICROSPHERES® expandable are polymer-based thermo-expandable microspheres with an average particle size of 5 to 50 μm, which are formed by encapsulating liquid hydrocarbon with a low boiling point in a shell of thermoplastic polymer. Various types are available, suitable for a wide temperature range, from low temperatures starting at about 80°C up to extremely high temperatures of about 260°C.

Application

Lightweight fillers for a wide range of applications in which a reduction in density, improvement in insulation as well as changes in mechanical properties and rheological properties are desired. The expandable hollow microspheres exhibit good temperature and solvent resistance, and exhibit comprehensive compatibility with a wide range of systems. The vast majority of MATSUMOTO MICROSPHERES® are available both dry (D-type) and wetted (unmarked) to best suit the application requirements.

| Products | Particle Size [μm] | Temperature min. [°C] | Temperature max. [°C] | Solvent resistance |

|---|---|---|---|---|

| Products expanding at low temperatures | ||||

| F-35 / F-35D | 10 – 20 | 70 – 80 | 100 – 110 | • |

| HF-36 / HF-36D | 10 – 16 | 70 – 80 | 110 – 120 | • |

| HF-48 / HF-48D | 9 – 15 | 90 – 100 | 125 – 135 | •• |

| FN-80GS / FN-80GSD | 6 – 10 | 100 – 110 | 125 – 135 | •• |

| Products expanding at medium temperatures | ||||

| FN-100SS / FN-100SSD | 6 – 10 | 120 – 130 | 145 – 155 | ••••• |

| FN-100S / FN-100SD | 10 – 20 | 125 – 135 | 150 – 160 | ••••• |

| FN-77 / FN-77D | 25 – 35 | 100 – 110 | 155 – 165 | ••• |

| FN-83GSD | 7 – 14 | 110 – 120 | 150 – 160 | ••• |

| FN-82 / FN-82D | 25 – 35 | 120 – 130 | 160 – 170 | ••• |

| FN-78 / FN-78D | 35 – 50 | 100 – 115 | 150 – 165 | ••• |

| Products expanding at higher temperatures | ||||

| FN-100M / FN-100MD | 20 – 30 | 125 – 135 | 165 – 180 | ••••• |

| FN-105 / FN-105D | 35 – 45 | 120 – 135 | 175 – 185 | ••• |

| FN-185L / FN-185LD | 35 – 50 | 140 – 150 | 180 – 190 | ••• |

| Products expanding at very high temperatures | ||||

| FN-190SSD | 10 – 15 | 155 – 165 | 210 – 220 | ••• |

| F-190D | 30 – 40 | 160 – 170 | 210 – 220 | ••• |

| F-230D | 25 – 35 | 180 – 190 | 220 – 240 | ••• |

| F-260D | 20 – 35 | 190 – 200 | 250 – 260 | ••• |

The values given are typical values and therefore do not represent a specification.

Solvent resistance: low: • medium: •• well suited: ••• recommended: •••••

OMEGA-SIL®

Description

OMEGA-SIL® are solid aluminium silicate spheres which have a very high compressive strength. The OMEGA-SIL® SPECIAL* product range consists of aluminium silicates that are processed in an additional processing step sifted. This particularly sharp separation of the top cut results in aesthetic applications to smoother surfaces.

Application

Due to the lower specific surface the use of OMEGA-SIL® in paints and coatings allows a higher degree of filling. OMEGA- SIL® shows in cementitious systems pozzolanic reactivity. The inside microcrystalline structure results in a significant increase of mechanical strength.

| Products | D50 [μm] | D95 [μm] | Effective density [g/cm³] | Bulk density [kg/m³] |

|---|---|---|---|---|

| OMEGA-SIL® XS | 3.5 | 9.5 | 2.51 | 780 |

| OMEGA-SIL® S | 4.5 | 11.5 | 2.48 | 800 |

| OMEGA-SIL® M | 6.5 | 30.0 | 2.40 | 870 |

| OMEGA-SIL® L | 12.5 | 75.0 | 2.39 | 880 |

| OMEGA-SIL® XL | 50.0 | 200.0 | 2.25 | 1,090 |

| OMEGA-SIL® XS SPECIAL | 3.5 | 9.5* | 2.51 | 780 |

| OMEGA-SIL® S SPECIAL | 4.5 | 11.5* | 2.48 | 800 |

| OMEGA-SIL® M SPECIAL | 6.5 | 30.0* | 2.40 | 870 |

Product items shown with an asterisk * describe top cut (d98) modified versions for aesthetical surfaces.

The stated values correspond to typical values and hence do not represent a specification.

LITHO-BUBBLES®

Description

LITHO-BUBBLES® are silicate based mineral granules. They are multicellular, open celled foam granulate which has many different uses as lightweight filler.

Application

LITHO-BUBBLES® are used as lightweight filler in aqueous, solvent-containing and solvent-free systems such as paints and coatings, refractory and foundry products, mould making, grinding agents or construction chemical products.

| Products | Particle size distribution [μm] | Bulk density [kg/m³] |

|---|---|---|

| LITHO-BUBBLES® 40 | 0 - 40 | 650 |

| LITHO-BUBBLES® 100 | 40 - 100 | 470 |

| LITHO-BUBBLES® 300 | 100 - 300 | 340 |

| LITHO-BUBBLES® 600 | 300 - 600 | 390 |

The stated values correspond to typical values and hence do not represent a specification.

LITHO-BUBBLES®, hydrophobic

Description

LITHO-BUBBLES® H is a hydrophobic mineral granule, multi-cellular, open-celled foam granulate which has many different uses as lightweight filler.

Application

LITHO-BUBBLES® are preferentially used as lightweight filler in aqueous but also in solvent-containing and solvent-free systems such as paints and coatings, refractory and foundry products, mould making, grinding agents or construction chemical products. Sometimes customer wish a hydrophobic treatment for special use in cement base systems for building and construction.

| Products | Particle size distribution [μm] | Bulk density [kg/m³] |

|---|---|---|

| LITHO-BUBBLES® 100H | 40 - 100 | 470 |

| LITHO-BUBBLES® 300H | 100 - 300 | 340 |

| LITHO-BUBBLES® 600H | 300 - 600 | 390 |

| LITHO-BUBBLES® 1000H | 500 - 1000 | 330 |

The stated values correspond to typical values and hence do not represent a specification.

Hollow glass spheres are produced in a process similar to our hollow ceramic microspheres. The standardised glass is transformed into a molten mass and transferred to a cooling chamber using a mist spray, which allows the material to solidify in this manner. The drop formation allows the material to expand to have a cavity, which has a strong acoustic and thermal insulating effect.

We recommend SPHERICEL types for use in aqueous systems, as these have an effective chemical composition against the attack of hydroxide ions.

Q-CEL®

Description

Q-CEL® are sodium borosilicate glass based hollow micro glass spheres which serve as a functional lightweight filler. An important property is their high mechanical resistance. The various Q-CEL® grades differ in density, particle size and compressive strength. Products with optimized particle size distributions can be selected if particularly high shear forces are required.

Application

Q-CEL® are used as weight-reducing fillers, for example, in paints and coatings, composites, potting and filling compounds, construction chemicals, syntactic foams, friction and brake linings, and many other applications. Q-CEL® 6014 is recommended for all resin systems where low viscosity and low shear forces are dominate. For medium shear environments, Q-CEL® 6019, 7019, 7023S and 5028 should be used. Q-CEL® 6717 and 6019S have reduced particle sizes and are used in applications with aesthetic surfaces.

Q-Cel

| Product | Effective Density [g/cm3] | Average Particle size [μm] | Particle Size [μm] (Malvern) | Pressure Resistance Isostatic [Psi] | Pressure Resistance Isostatic [Mpa] |

|---|---|---|---|---|---|

| Q-CEL® 300 | 0.21 | 90 | 5 - 200 | 500 | 3.4 |

| Q-CEL® 6014 | 0.14 | 85 | 5 - 200 | 250 | 1.7 |

| Q-CEL® 6019 | 0.19 | 75 | 5 - 175 | 500 | 3.4 |

| Q-CEL® 6019S | 0.19 | 70 | 5 - 150 | 500 | 3.4 |

| Q-CEL® 6020FPS | 0.2 | 45 | 5 - 90 | 500 | - |

| Q-CEL® 6717 | 0.19 | 52 | 5 - 105 | 500 | 3.4 |

| Q-CEL® 5028 | 0.25 | 75 | 5 - 120 | 750 | 5.2 |

| Q-CEL® 6028 | 0.28 | 70 | 5 - 150 | 750 | - |

| Q-CEL® 6036 | 0.36 | 60 | 5 - 125 | 1,000 | 6.8 |

| Q-CEL® 6042S | 0.42 | 50 | 5 - 90 | 2,000 | 13.8 |

| Q-CEL® 6048 | 0.48 | 50 | 5 - 100 | 3,000 | 20.7 |

| Q-CEL® 5070S | 0.7 | 35 | 10 - 100 | 3,500 | 24.2 |

| Q-CEL® 5019 | 0.19 | 72 | 5 - 150 | 500 | - |

| Q-CEL® 5032S | 0.32 | 63 | 5 - 150 | 1,000 | - |

| Q-CEL® 7019 | 0.19 | 80 | 5 - 150 | 500 | 3.4 |

| Q-CEL® 7023S | 0.23 | 85 | 5 - 120 | 750 | 5.2 |

| Q-CEL® 7028 | 0.27 | 75 | 5 - 120 | 1,000 | - |

| Q-CEL® 7036 | 0.36 | 63 | 5 - 125 | 1,000 | - |

| Q-CEL® 7040S | 0.4 | 54 | 5 - 100 | 2,000 | 13.8 |

The stated values correspond to typical values and hence do not represent a specification.

SPHERICEL®

Description

SPHERICEL® are borosilicate glass-based hollow microspheres manufactured in a special process, which serve as a functional filler. In addition to a very high mechanical resistance, SPHERICEL® micro hollow glass spheres are hydrophobic and, in comparison to other hollow spheres, exhibit a significantly increased resistance to aqueous media. SPHERICEL® grades differ in density, particle size and pressure resistance, so that they can be selected specifically for the application and the associated requirements.

Application

SPHERICEL® micro hollow glass beads are used as lightweight fillers in high-quality syntactic foams, paints and coatings, fillers, potting and molding compounds. In friction and brake linings as well as abrasives. SPHERICEL® micro hollow glass beads can be used as pore formers. The exceptionally high mechanical resistance also allows the use in compound or composite materials, such as SMC / BMC as well as plastic compounds.

| Product | Effective Density [g/cm3] | Average Particle size [μm] | Particle Size [μm] (Malvern) | Pressure Resistance Isostatic [Psi] | Pressure Resistance Isostatic [Mpa] |

|---|---|---|---|---|---|

| SPHERICEL® 110P8 | 1.1 | 12 | 2 - 25 | 10,000 | 69 |

The stated values correspond to typical values and hence do not represent a specification.

OMEGA-BUBBLES® C - ultra white

OMEGA-BUBBLES® C are multicellular expanded glass granules. The high whiteness can help to reduce the addition of titanium dioxide in cementitious formulation. For aesthetic applications like acoustic construction or ceilings the ultra-white lightweight fillers meet today's spirit of time. OMEGA-BUBBLES® C being based on selected recycled glass. Using these products is sustainable and environmentally friendly and can reduces your green CO2 footprint in later disposal issues.

OMEGA-BUBBLES® C are available in the grain sizes customary on the market for the construction and insulation industry.

| Products | Particle size range [mm] | Grain gross density [kg/m³] | Bulk density [kg/m³] |

|---|---|---|---|

| OMEGA-BUBBLES® C-XS | 0.1 - 0.3 | 680 - 920 | 340 - 460 |

| OMEGA-BUBBLES® C-S | 0.25 - 0.5 | 460 - 620 | 255 - 345 |

| OMEGA-BUBBLES® C-M | 0.5 - 1.0 | 380 - 510 | 210 - 290 |

| OMEGA-BUBBLES® C-L | 1.0 - 2.0 | 310 - 420 | 190 - 250 |

| OMEGA-BUBBLES® C-XL | 2.0 - 4.0 | 260 - 360 | 160 - 220 |

The stated values correspond to typical values and hence do not represent a specification.

LUVOFIL® TEC – Unique Class of Multi-purpose Functional Fillers

LUVOFIL® TEC comprises a portfolio of multi-purpose functional fillers based on the world’s first polymer foam with pores in the nanometer range. Produced based on a patent-protected process and foamed with a 100% climate-friendly blowing agent, an entirely new class of materials with a pore size reduction of the factor 1000 compared to conventional polymer foams is provided leading to a unique and multi-purpose performance profile.

Product overview:

| Products | Description | Particle Size D50 [µm] | Particle Size D100 [µm] | Application |

|---|---|---|---|---|

| LUVOFIL® TEC 50 | LUVOFIL® TEC 50 is a foamed, highly hydrophobic, thermoplastic polymer delivered as white powder with the lowest tamped density possible. | <15 | <50 | LUVOFIL® TEC 50 is used to achieve deep matting at highest transparency, anti-burnishing, mar, scratch, and scuff resistance, water repellency, water and chemical resistance, as well as water vapor permeability for water-based and solvent-free paints and coatings. Furthermore, LUVOFIL® TEC 50 is applied as matting and rheology control agent (fumed silica replacement) in SMP and silicone-based sealants. Applied as functional filler in cementitious and blow-in insulation systems as well as tile adhesives, LUVOFIL® TEC 50 offers weight reduction, thermal insulation and diffusion-open barrier properties. |

| LUVOFIL® TEC 300 | LUVOFIL® TEC 300 is a foamed, highly hydrophobic, thermoplastic polymer delivered as white powder with the lowest tamped density possible. | <300 | LUVOFIL® TEC 300 is used as functional filler in order to provide weight reduction, thermal insulation and diffusion-open barrier properties in cementitious and blow-in insulation systems as well as tile adhesives. Furthermore, LUVOFIL® TEC 300 is applied as liquid carrier for powder coatings, masterbatches, and compounding with the ability to absorb more than 600 w% liquid depending on its chemical nature, polarity and viscosity. | |

| LUVOFIL® TEC 1000 | LUVOFIL® TEC 1000 is a foamed, highly hydrophobic, thermoplastic polymer delivered as white powder with the lowest tamped density possible. | <1,000 | LUVOFIL® TEC 1000 is used as functional filler in order to provide weight reduction, thermal insulation and diffusion-open barrier properties in cementitious and blow-in insulation systems as well as tile adhesives. Furthermore, LUVOFIL® TEC 1000 is applied as liquid carrier for powder coatings, masterbatches, and compounding with the ability to absorb more than 600 w% liquid depending on its chemical nature, polarity and viscosity. |